.gtranslate_wrapper

AUTOMATION SYSTEMS

Manipulator precision calibration, motion optimization, control system upgrades

OUR AUTOMATION SYSTEMS

WHY CHOOSE

AUTOMATION SYSTEMS?

Your top choice for smart automation!

Jaeden Higgins

“Thanks to Jieyimei Laser and the technical team, our project has benefited from the precise performance of metal resistance elements.

How Our Laser Machines Work

Feeding system

Engineered for Precision & Performance

Seeking to ensure your automated handling projects run flawlessly? Our manipulator systems are the cornerstone of the process. They streamline material transfer, position components with micron-level accuracy, and integrate seamlessly into production lines—eliminating manual errors.

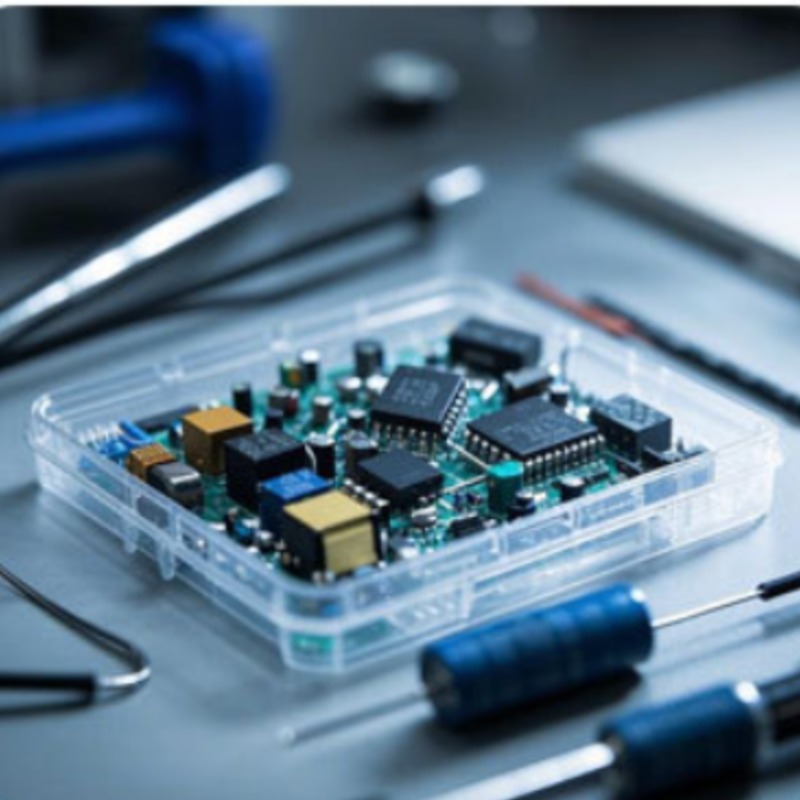

We use advanced calibration technology to optimize motion paths. Just like how 3D coordinate measuring machines verify part dimensions in precision engineering, our manipulator calibration systems ensure every movement is exact, with repeatability within ±0.02mm. This sets the stage for stable, high-quality automation—critical for tasks like electronics assembly or heavy part handling.

- Precision Motion Control: Smooth, accurate movements for consistent component positioning.

- Consistent Results: Reliable handling to reduce defects in final products.

- Custom Solutions: Adaptable to different part sizes, weights, and production line layouts.

Visual system

Precision Engineered for Reliability

In automated manufacturing, our visual systems act as the “eyes” of manipulator operations, ensuring every handling, assembly, or sorting task is executed with pinpoint accuracy. After components are positioned or materials are prepared, the visual system takes center stage—guiding manipulators to act with unmatched precision.

- Dynamic Recognition: Ideal for high-speed production lines (e.g., logistics sorting, bulk material transfer). It swiftly identifies moving objects by shape, barcode, or color, enabling manipulators to adjust actions in real time—boosting throughput for mass production.

- Static Positioning: Perfect for precision tasks (e.g., electronics assembly, small part alignment). It captures detailed 2D/3D coordinates of stationary components, guiding manipulators to achieve micron-level placement accuracy—critical for intricate assembly work.

Engineered for Precision Performance

Manufacturing with automation? Accuracy in handling and assembly is non-negotiable. After material transfer and component positioning, our final step ensures 1:1 precision in every operation—matching your production specifications down to the smallest detail.

- Precision Execution: Micron-level positioning that aligns perfectly with design blueprints, ensuring components fit together seamlessly.

- Consistent Quality: No misalignments, no errors—just reliable, repeatable results that reduce rework and boost product integrity.

- Custom Adaptability: From one-of-a-kind prototypes to high-volume mass production, the system adapts to your unique workflow, whether it’s delicate assembly or heavy-load transfer.

Notice the difference in our automated precision? Ready to elevate your production line with 100% reliable, accurate automation?

Pre-Sales Consultant

Certain industries present unique challenges when it comes to processing advising. For...

Material Testing

Material is what you need to pay the most attention to. You can find the laser ability of most...

Training

Your competitiveness is not only affected by the laser machines but also driven by yourself. As you...

Installation

The installation of any machinery is a decisive phase and must be carried out correctly and in the...

After-Sales

After your purchase, MimoWork will provide the customers with our full-range service and get...

Spare Parts

Jieyimei is committed to providing you with the best standard spare parts. As long as...

Extended Warranty

Jieyimei is dedicated to design and produce long-lifespan laser machines to boost their...

On-site Services

Jieyimei backs our laser machines with general on-site services including installation...

Choose A Reliable Manufacturer

Choose A Reliable Manufacturer

Customers We Serve

Xiefu provides top-tier global services, with a growing customer base spanning industries worldwide—from small-scale workshops and design firms to large manufacturing enterprises in electronics, automotive, logistics, and textiles. We’re committed to understanding your unique production needs, adapting our solutions to your workflows, and turning your automation goals into reality.

Factory Display

Quality - Driven Sample and Certification Processes

Why choose us?

Processing capacity

Our strong production capabilities enable us to meet all of your project requirements from prototype to production.

On time delivery

We value and understand the importance of on-time delivery, so we will make a suitable production plan for your project.

Excellent experience

Our experts will assist you and respond to your inquiries promptly, bringing you an exceptional customer experience.

What services can we provide

Short Delivery Time: With a physical factory, we have strong production capacity and sufficient inventory.

Adequate Capacity: We reject false labeling and ensure rated capacity.

Authoritative Certification: Passed various authoritative certifications, meeting international standards.

Customizability: Dimensions, capacity, protection board, and other requirements can be customized according to customer needs.

Quality Assurance: We build a comprehensive quality system from parts to finished products to ensure product quality.

Perfect Service System: We respond quickly to customer questions and provide solutions.

Streamline Your Post-Processing Workflow

- Accurate materials labeling by digital control

- Ideal for shortening subsequent sewing or alignment

- Various materials can be marked onto

- Available for different colors and shapes

Our Value

Professional

Means doing what's right, not what's easy. With this spirit, Jieyimei also shares laser knowledge with ourcustomers, distributors, and staff group. You can check our technical articles regularly on Jieyimei-Pedia.

International

Jieyimei has been a long-term partner and laser system supplier for numerous demanding industrial companies on a worldwide basis. We invite global distributors for mutually beneficial business partnerships. Check our Service details.

Trust

Is something we earn every day through open and honest communication and by putting our clients’ needs above our own.

Pioneering

We believe that expertise with fast-changing, emerging technologies at the crossroads of manufacture, innovation, technology, and commerce are a differentiator.