.gtranslate_wrapper

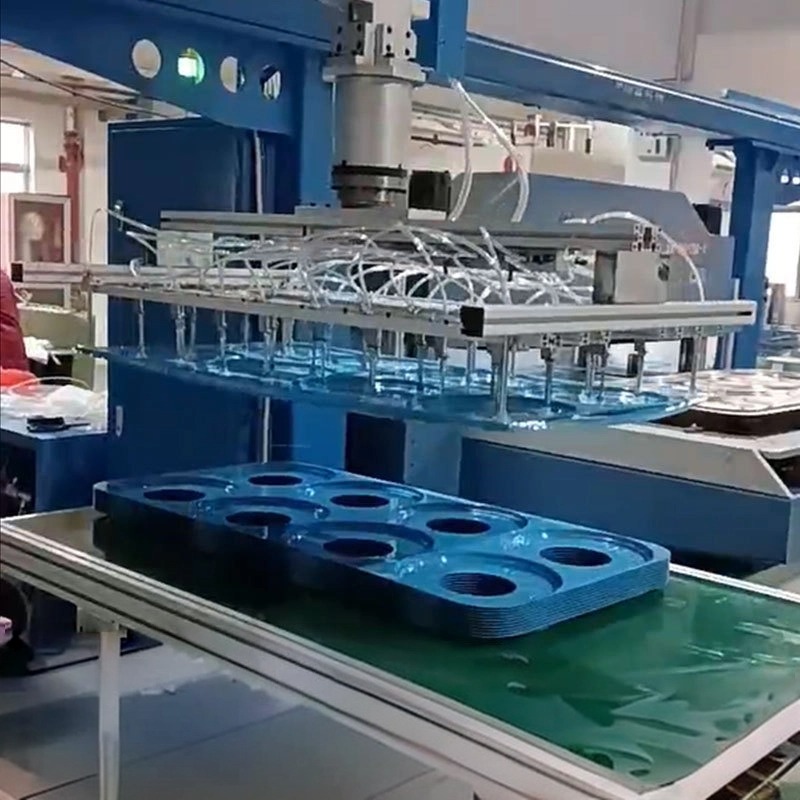

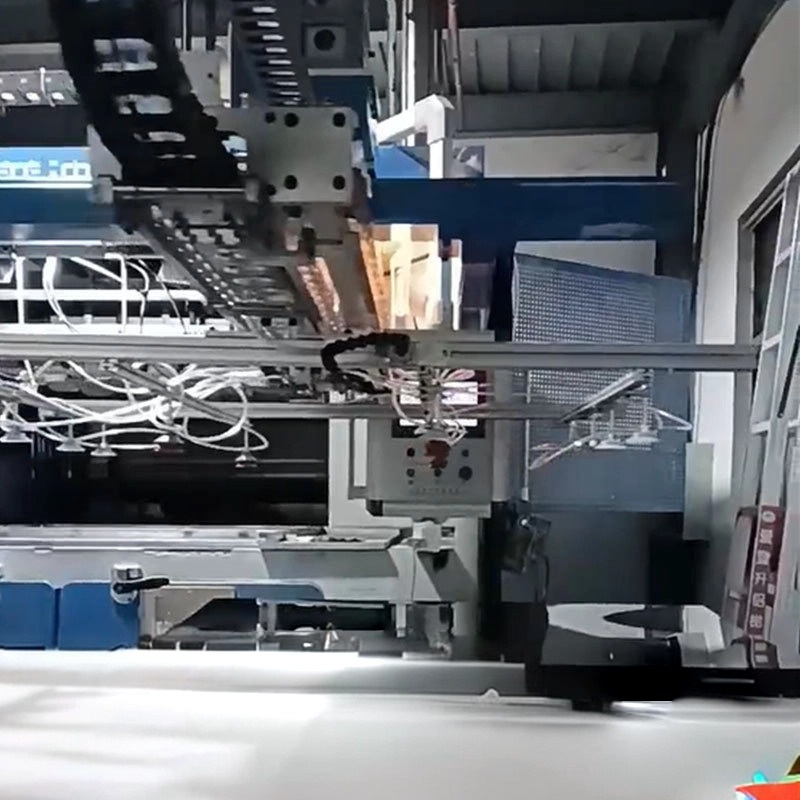

Automation-Handled Workpieces

"Finished Showcase: Precisely Handled Workpieces with Stable Quality & Consistent Standard"Feeding System

Automated Material Handling for Manipulators

"Stable Feeding. Ensuring Efficient Material Transfer for Seamless Production"Visual System Handling

Process of Manipulator Operations

"Visual Guidance: High-Precision Handling via Intelligent Image Recognition"High Quality

Top – notch laser tech ensures flawless cuts, every time.

Fast Delivery

Quick, accurate cuts, no delays. Meet tight deadlines with ease.

Best Warranty

Reliable machines + great warranty. Worry – free cutting, always.

About me

Dongguan Xiefu Machinery Co., Ltd. specializes in automation robot solutions for manufacturing. Founded with a focus on intelligent production, we boast professional R&D teams and a track record of developing multi-axis manipulators (three-axis, two-axis) and integrated automation systems. Our production base supports the delivery of reliable, high-performance equipment, tailored to solve manufacturing pain points like inefficient handling and unstable assembly. Committed to merging technology with practicality, we empower factories with seamless, intelligent automation—making production smarter, faster, and more consistent.

XieFu Delivers The Future to You

Employee First

Customer Foremost

Quality Priority

Glory the Country

TWO-AXIS MANIPULATORS

AUTOMATED ASSEMBLY

AUTOMATED SORTING

What are You Trying to Do ?

Find the Process That aligns your Production & Needs

Articulated robot

Highly flexible multi-axis robotic solutions for precise material handling, assembly, and seamless integration into automated workflows, enhancing production agility and accuracy.

Plastic Machinery Auxiliaries

Precision cutting systems engineered for diverse materials, delivering clean edges, consistent results, and optimized throughput in high-volume manufacturing environments.

Cutting machine

Essential support equipment for plastic processing lines, streamlining material handling, drying, and auxiliary processes to maximize production efficiency and quality control.

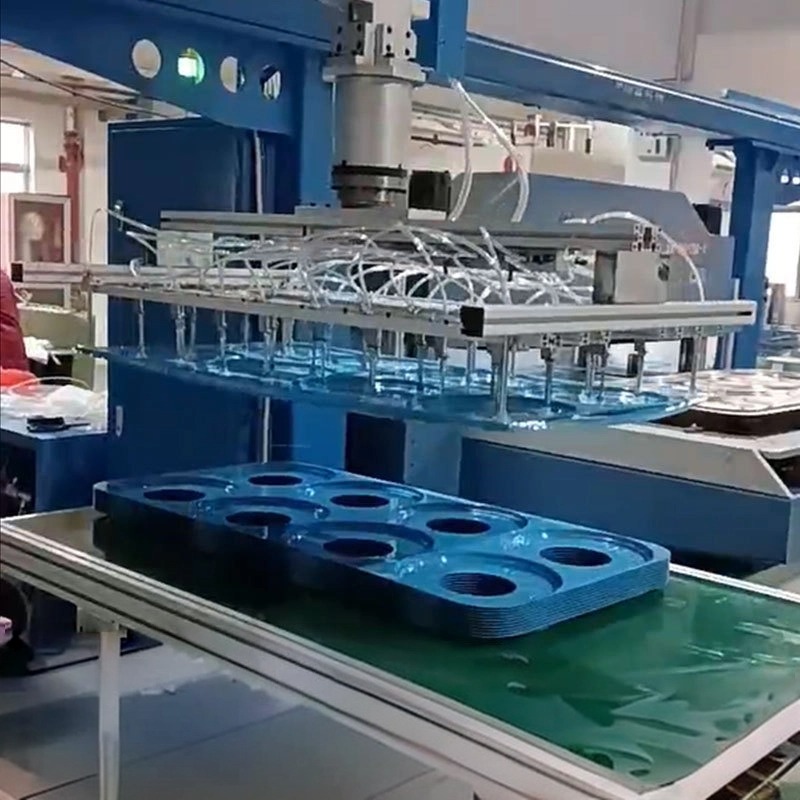

Plastic vacuum

forming machine

Advanced thermoforming solutions for crafting precise plastic components, ideal for packaging, automotive, and consumer goods industries with customizable forming capabilities.

▍ Application Examples

–digital printing

food packaging

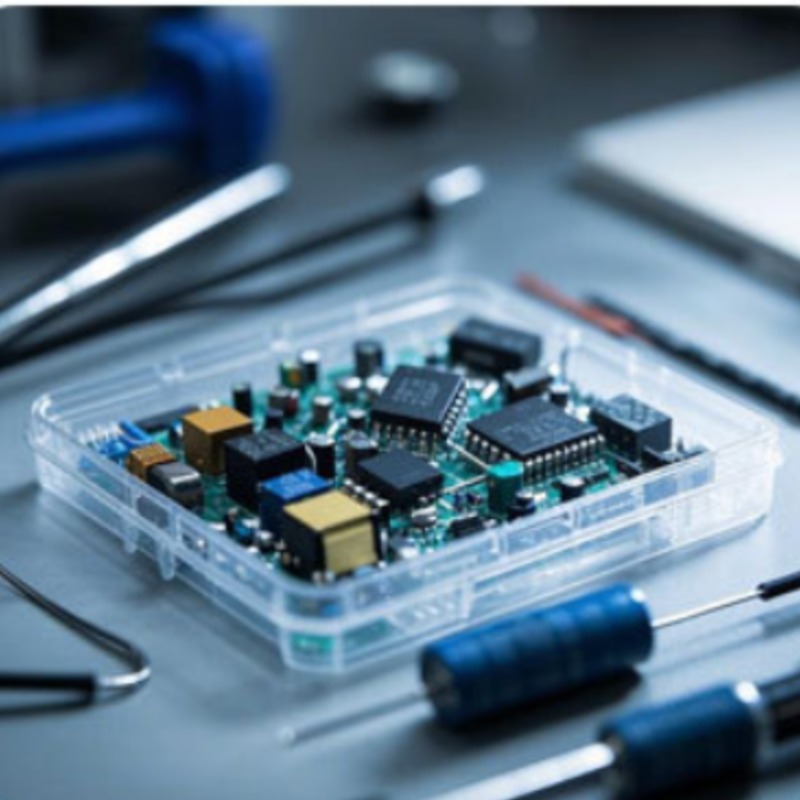

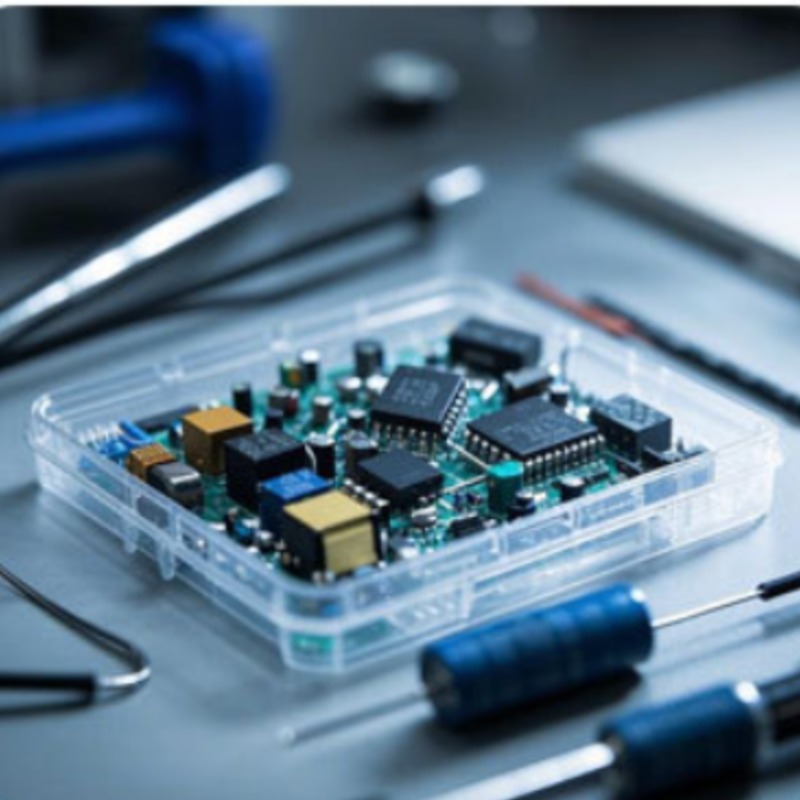

Automated loading/unloading of circuit boards, precise assembly of small components, sorting of electronic parts by specifications.

medical supplies

Handling auto parts (bolts, gaskets), assembly of interior components, sorting of metal fittings by size.

electronic element

Sorting packages by weight/barcode, automated palletizing, loading/unloading of cartons.

daily necessities

Assembly of small parts (switches, knobs), loading/unloading of panels, sorting of finished products by model.

Our latest products

Application Examples

—— Plush Toy Our Fabric Laser Cutting

Elevate your electronics production with our high-precision two-axis Cartesian manipulators. At Dongguan Xiefu Machinery, we specialize in automated handling for electronics assembly, ensuring stable part transfer, accurate alignment, and consistent efficiency in every process. Our manipulators, integrated with reliable components (Mitsubishi PLC, Delta servo motors), handle small parts like capacitors, resistors, and connectors with unmatched precision, streamlining your assembly line.

-Smart Logistics Sorting: Where Speed Meets Accuracy

With rapid response and intelligent visual recognition, our manipulators sort logistics packages flawlessly. Whether by size, weight, or barcode, each sorting step is executed with precision, boosting warehouse throughput and reducing manual errors. Perfect for e-commerce fulfillment or manufacturing logistics.

- Automotive Parts Loading/Unloading

Showcasing robust manipulator systems, ideal for automotive component handling.

-Industrial Robot Systems: Safe, Durable, and Built for Productivity

Design

Our Upgradess

Upgrade Options Designed for Efficiency

Vision System

Contour Recognition Template Matching

Software

Seamless Integration with User Friendly Setup

Table Concepts

Fully Customizable Sizes and Types

Exhaust System

Clean, Safe and Refreshing Working Environment

Feeding System

Alignment Correction and Tension Control

Operational Training

Training Program with Technician and Video

Xiefu

Precision Manipulators for Smart Manufacturing

“Where Efficiency Meets Reliable Automation!!”

Materials for Manipulator Handling

If you work with specialized materials not listed here and need to confirm compatibility, please don’t hesitate to reach out to our technical team for tailored material handling tests.

Narrow down the Best Option for your Production

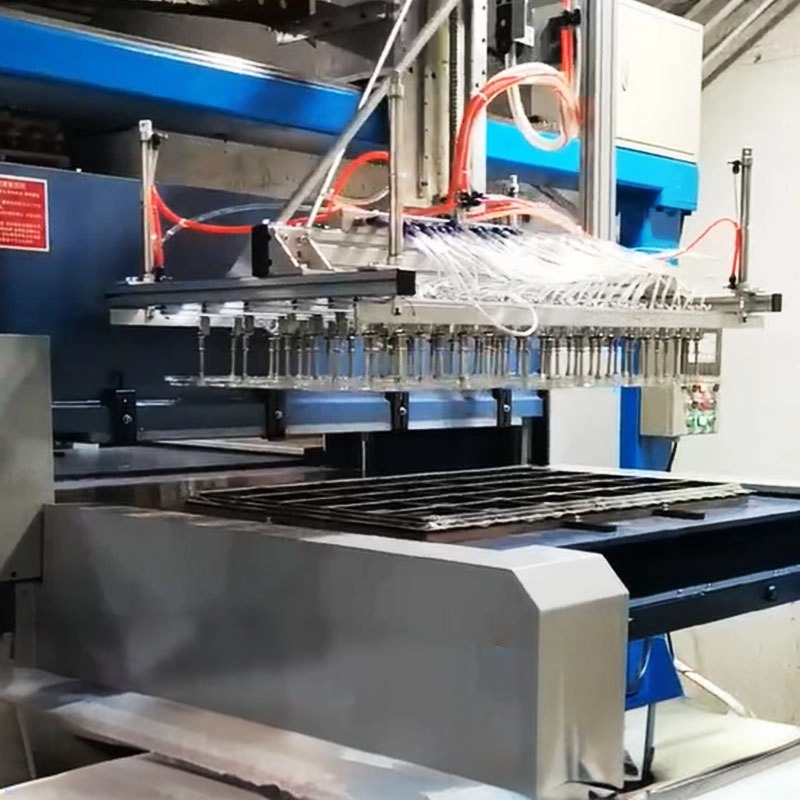

Large - scale industrial machinery, powerful and efficient.

Industrial equipment, showcasing advanced manufacturing.

Large-Scale Automation Manipulator Systems

Industrial Automation Equipment

Our Clients Believe In Us

HERE IS WHAT

THEY ARE SAYING

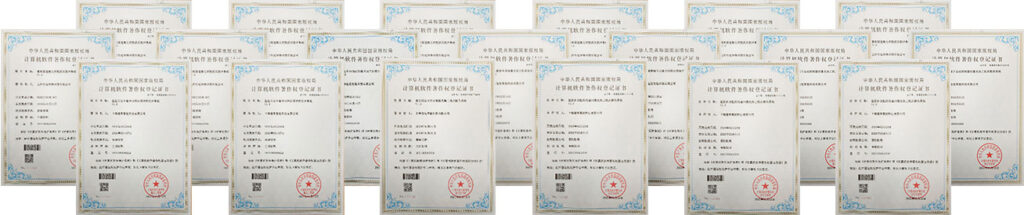

Certificate & Patent

Specialized Automation Patents, CE & ISO Certifications

Xiefu Robotic Solutions – Successful On-Site Installation in Indonesia

We are excited to share a

Why Smart Automation Is the Key to Solving Today’s Factory Challenges

Manufacturers today face

SpeedInManufacturing Xiefu: How Robotic Arms Accelerate Production Efficiency

Time is money in the manu

Subscribe to Fresh Newsletter

Proin eget tortor risus cras ultricies ligula sed magna dictum porta sed porttitor lectus nibh vamus suscipit tortor.